Services

Comprehensive Plastic Injection Molding Solutions Across Industries

1

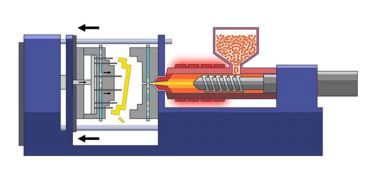

Plastic Injection Molding

Plastic Injection Molding is a highly efficient manufacturing process for producing precise and durable plastic components in large volumes. By injecting molten plastic into custom-designed molds, this technique ensures consistency, accuracy, and scalability. Ideal for industries ranging from automotive to consumer goods, it delivers cost-effective solutions with exceptional quality and versatility, meeting diverse application needs.

2

Design & Prototyping

Design & Prototyping is the cornerstone of innovation, transforming concepts into tangible solutions. This service encompasses the entire creative journey, from ideation and 3D modeling to rapid prototyping and iterative design refinement. By leveraging advanced tools and technologies, it ensures that ideas are thoroughly tested, optimized, and ready for production, delivering tailored solutions that align with client needs and market demands.

3

Material Expertise

Material Expertise is the foundation of creating reliable and high-performance products. With specialization in standard plastics, engineering plastics, and eco-friendly bioplastics, this service ensures optimal material selection tailored to specific applications. By balancing durability, functionality, and sustainability, it enables the development of innovative solutions that meet technical and environmental requirements.

4

Assembly & Finishing

Assembly & Finishing focuses on delivering complete, market-ready products through meticulous post-production processes. From assembling components with precision to applying finishing touches like painting, coating, or polishing, this service ensures both functionality and aesthetic appeal. With a commitment to quality assurance, it guarantees that every product meets the highest standards before reaching the end user.